J-31-C

SOJET

| EXPLANATORY VIDEO | ||

| | ||

| PILLOW PACKING LINE | ||

| The pillow vacuum compression packaging machine is used for compression and sealing packaging of pillows, cushions, back cushions, quilts, down quilts, space quilts and other items, thereby reducing packaging costs, saving storage space and reducing transportation costs. Our machine stands out with its fully automated capabilities, including automatic material feeding, compression, and sealing. This seamless automation not only accelerates the packaging process but also ensures that each pillow is uniformly compressed and securely sealed, maintaining product integrity and presentation. Designed for ease of use, the machine is operated by a single individual, significantly reducing labor requirements. Its intuitive control panel and automated features allow for minimal oversight, making it an excellent choice for businesses seeking to enhance their operational efficiency without compromising on quality. A dedicated water cooling system is integrated into the machine to ensure the longevity and quality of the seal. This system is crucial in maintaining the optimal temperature during the sealing process, preventing any potential damage to the pillow's material and ensuring a consistent, high-quality finish. | ||

| ||

SUITABLE PRODUCTS SUITABLE PRODUCTS | ||

| ||

| TECHNICAL SPECIFICATIONS | ||

| MODEL | J-31-C | J-31-D |

| Power | 1.0Kw | 1.0Kw |

| Capacity | 250-300 pillows/hour | 200-450 pillows/hour |

| Sealing Size (custom) | 800x800mm | 1200x1200mm |

| Air Pressure | 0.4-0.8 MPa | 0.6-0.8 MPa |

| Dimensions (L*W*H) | 1020x1020x1560mm | 1430x1310x2020mm |

| FEATURES OF PILLOW PACKING MACHINE | ||

| ● Built-in with infeed conveyor belt, it can make sure the pillows are transporting in a right line to the compress process. | |

| ● PLC & Touch-screen Control System in both Chinese and English version, you can choose one of them for using. And it is easy to set the packing parameter via this screen. | |

| ● These J-31-C automatic air-pressure packing machine is able to change the compress thickness and it can be be adjusted according to different kinds of packing products, such as towels, sofa cushions, dog beds, pillows, mattress covers, etc. | |

| ● This compress machine is with a double-cylinder for sealing purpose, so that to ensure the flat sealing effect of compressed pillows and cushions, and keeps thethem looks perfectly with our special design of water cooling system at the machine. | |

| ● The machines can be adjusted to accommodate different pillow sizes and shapes, the compression table plate will be custom as per your actual product dimension and the weight, even for the conveyor belt can be also custom based on your production needs. | |

| PROJECT CASES | ||

|  |  |

| 2013 in Dubai | 2014 in USA | 2015 in India |

|  |  |

| 2017 in Russia | 2018 in Korea | 2019 in Spain |

|  |  |

| 2020 in Malaysia | 2021 in India | 2023 in Indonesia |

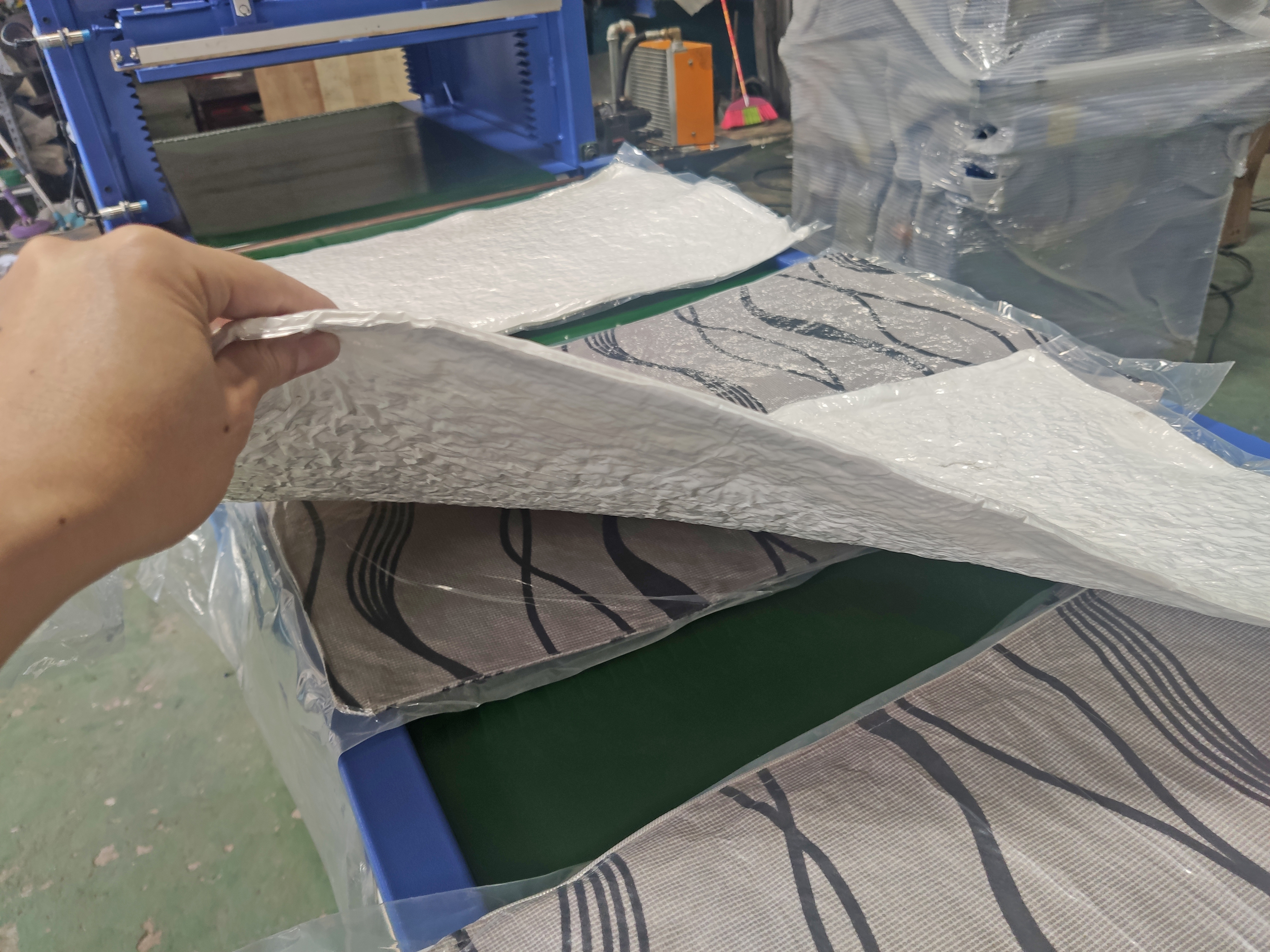

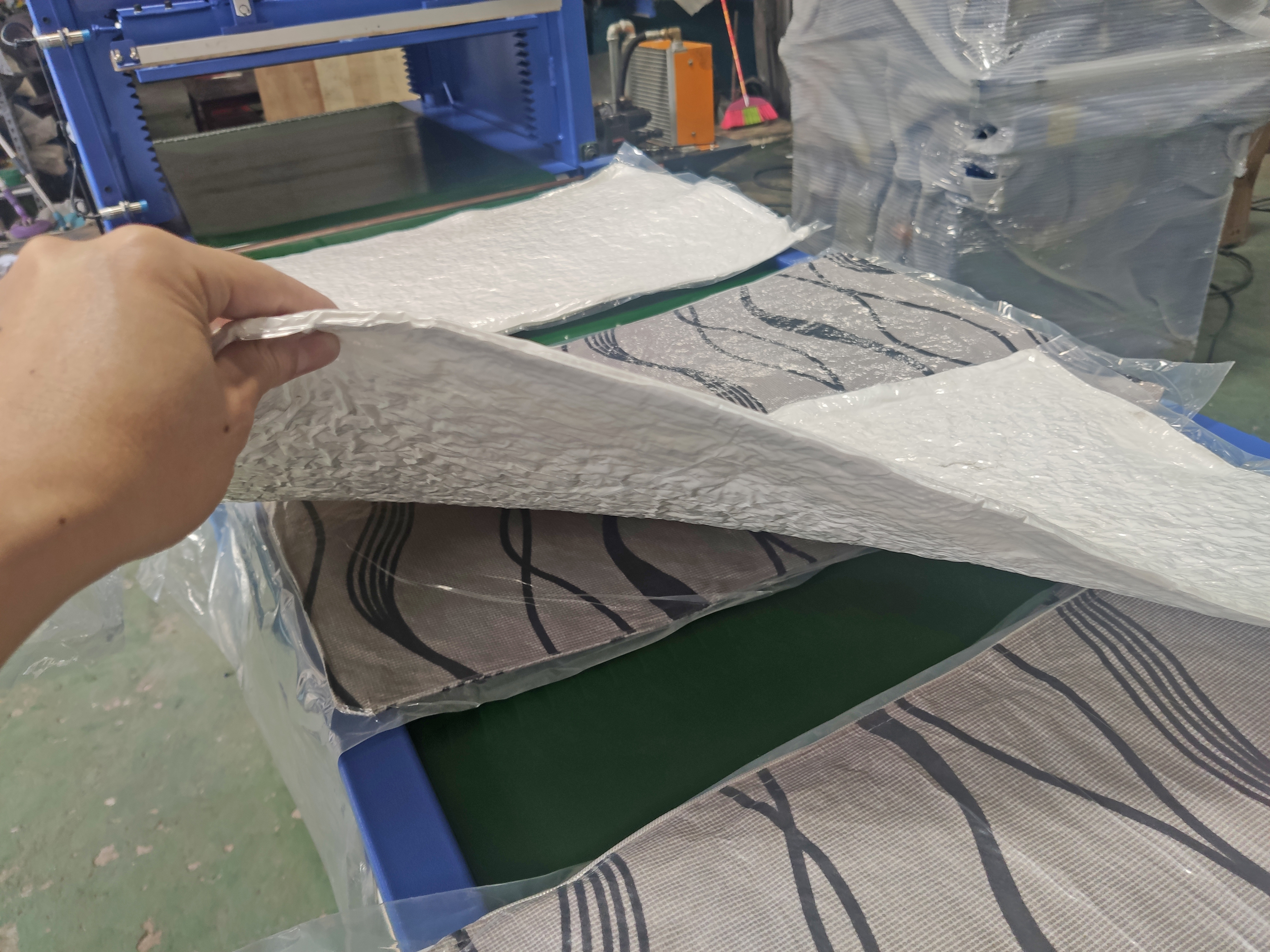

| FINISHED PRODUCTS | |||

|  |  |  |

| EXPLANATORY VIDEO | ||

| | ||

| PILLOW PACKING LINE | ||

| The pillow vacuum compression packaging machine is used for compression and sealing packaging of pillows, cushions, back cushions, quilts, down quilts, space quilts and other items, thereby reducing packaging costs, saving storage space and reducing transportation costs. Our machine stands out with its fully automated capabilities, including automatic material feeding, compression, and sealing. This seamless automation not only accelerates the packaging process but also ensures that each pillow is uniformly compressed and securely sealed, maintaining product integrity and presentation. Designed for ease of use, the machine is operated by a single individual, significantly reducing labor requirements. Its intuitive control panel and automated features allow for minimal oversight, making it an excellent choice for businesses seeking to enhance their operational efficiency without compromising on quality. A dedicated water cooling system is integrated into the machine to ensure the longevity and quality of the seal. This system is crucial in maintaining the optimal temperature during the sealing process, preventing any potential damage to the pillow's material and ensuring a consistent, high-quality finish. | ||

| ||

SUITABLE PRODUCTS SUITABLE PRODUCTS | ||

| ||

| TECHNICAL SPECIFICATIONS | ||

| MODEL | J-31-C | J-31-D |

| Power | 1.0Kw | 1.0Kw |

| Capacity | 250-300 pillows/hour | 200-450 pillows/hour |

| Sealing Size (custom) | 800x800mm | 1200x1200mm |

| Air Pressure | 0.4-0.8 MPa | 0.6-0.8 MPa |

| Dimensions (L*W*H) | 1020x1020x1560mm | 1430x1310x2020mm |

| FEATURES OF PILLOW PACKING MACHINE | ||

| ● Built-in with infeed conveyor belt, it can make sure the pillows are transporting in a right line to the compress process. | |

| ● PLC & Touch-screen Control System in both Chinese and English version, you can choose one of them for using. And it is easy to set the packing parameter via this screen. | |

| ● These J-31-C automatic air-pressure packing machine is able to change the compress thickness and it can be be adjusted according to different kinds of packing products, such as towels, sofa cushions, dog beds, pillows, mattress covers, etc. | |

| ● This compress machine is with a double-cylinder for sealing purpose, so that to ensure the flat sealing effect of compressed pillows and cushions, and keeps thethem looks perfectly with our special design of water cooling system at the machine. | |

| ● The machines can be adjusted to accommodate different pillow sizes and shapes, the compression table plate will be custom as per your actual product dimension and the weight, even for the conveyor belt can be also custom based on your production needs. | |

| PROJECT CASES | ||

|  |  |

| 2013 in Dubai | 2014 in USA | 2015 in India |

|  |  |

| 2017 in Russia | 2018 in Korea | 2019 in Spain |

|  |  |

| 2020 in Malaysia | 2021 in India | 2023 in Indonesia |

| FINISHED PRODUCTS | |||

|  |  |  |