J-001-D2

SOJET

| EXPLANATORY VIDEO | ||

| | ||

| PILLOW FILLING LINE | ||

Automatic Pillow Production Line Suitable for hcs fiber 0.7d~15d, 32-64mm (fiber & microfiber) Power: 19.5Kw Capacity: 240 pcs/hour Pillow weight: 300g-1500g Max. pillow size: 940x1150mm Filling thickness: 175-250mm Voltage: 380V,50Hz, three-phase Certificate: CE Tolerance: <15g (80% less than 10g.) Dimensions (L*W*H): 5500*5500*4250mm This model is a machine designed to automatically fill pillows or cushions. - The machine equipped the high tech and new weight setting devices, easy to set the weight for each pillow or cushion | ||

| ||

| SUITABLE TYPES OF FIBERS FOR FILLING | ||

| ||

| TECHNICAL SPECIFICATIONS | ||

| MODEL | J-001-D1 | J-001-D2 |

| Power | 19.5Kw | 19.5Kw |

| Capacity | 200 pillows/hour | 240 pillows/hour |

| Filling Nozzle | One nozzle | Two nozzles |

| Operator | 1 person | 1 person |

| Pillow Weight | 300g-1500g | 300g-1500g |

| Dimensions (L*W*H) | 5500*5300*4250mm | 5500*5300*4250mm |

| FEATURES OF PILLOW PRODUCTION LINE | ||

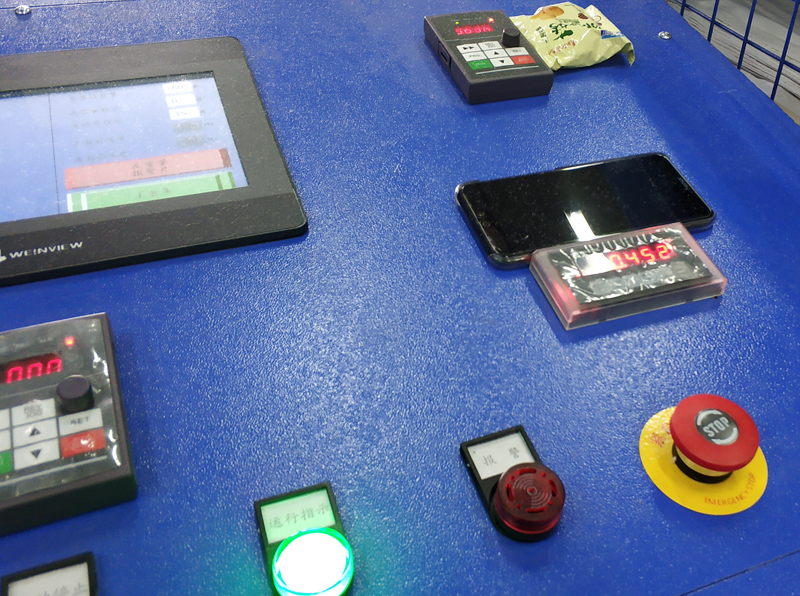

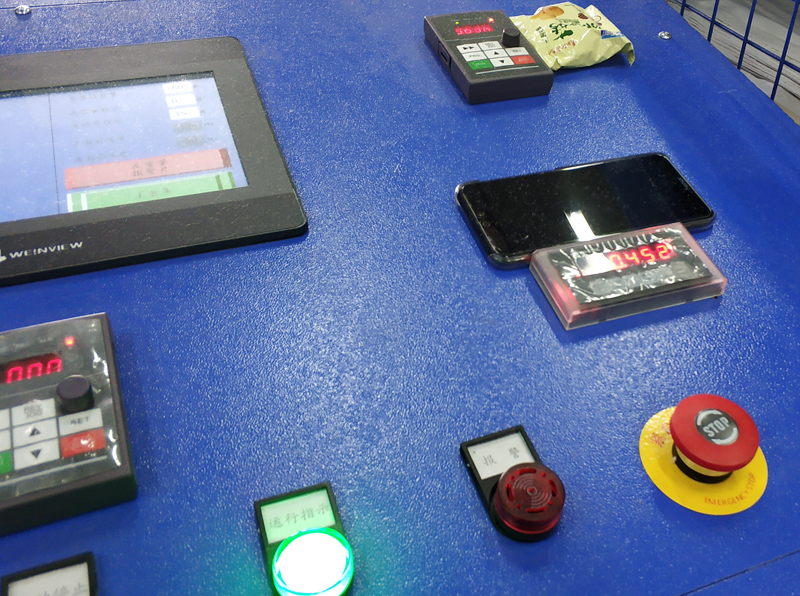

| ● PLC Control System The production line is controlled by PLC programming system , which is automatically feeding (polyester, microfiber,kapok), opening, weighing and filling . The weight can be set on the control box, and it's simple operated and with high efficiency. | |

| ● Accurate Weighing We use the quality weight sensor and the machine's weighing error/tolerance is less than 15 grams per filling. The material weighing speed is faster and it's accurate to ensure output of materials and the quality of fibers. | |

| ● High Efficiency This J-001-D2 highest filling capacities ranging from 1,000 pillows to 4,000 pillows per shift, from bale opening, carding, weighing and filling process, it can all controlled on the control box with only onesingle operator. | |

| ● Vacuum Filling Polyester fiber comes inevery corner of the pillow, by using our pillow production line, the pillow is more even, full and flat. This machine is suitable for pillowcases of various fabrics, fabric, nonwoven fabric, etc. There is no fiber flying in the filling process, clean and environmental protection. | |

| ● Automatic Feeding The bale opener can store 250-300kg fiber per hour, the fiber will be infeeded evenly to the fiber opener without manual feeding, saving labor cost. | |

| PROJECT CASES | ||

|  |  |

| 2013 in Dubai | 2014 in USA | 2015 in India |

|  |  |

| 2017 in Russia | 2018 in Korea | 2019 in Spain |

|  |  |

| 2020 in Malaysia | 2021 in India | 2023 in Indonesia |

| EXAMPLES OF FINAL PRODUCTS | ||

| ||

| EXPLANATORY VIDEO | ||

| | ||

| PILLOW FILLING LINE | ||

Automatic Pillow Production Line Suitable for hcs fiber 0.7d~15d, 32-64mm (fiber & microfiber) Power: 19.5Kw Capacity: 240 pcs/hour Pillow weight: 300g-1500g Max. pillow size: 940x1150mm Filling thickness: 175-250mm Voltage: 380V,50Hz, three-phase Certificate: CE Tolerance: <15g (80% less than 10g.) Dimensions (L*W*H): 5500*5500*4250mm This model is a machine designed to automatically fill pillows or cushions. - The machine equipped the high tech and new weight setting devices, easy to set the weight for each pillow or cushion | ||

| ||

| SUITABLE TYPES OF FIBERS FOR FILLING | ||

| ||

| TECHNICAL SPECIFICATIONS | ||

| MODEL | J-001-D1 | J-001-D2 |

| Power | 19.5Kw | 19.5Kw |

| Capacity | 200 pillows/hour | 240 pillows/hour |

| Filling Nozzle | One nozzle | Two nozzles |

| Operator | 1 person | 1 person |

| Pillow Weight | 300g-1500g | 300g-1500g |

| Dimensions (L*W*H) | 5500*5300*4250mm | 5500*5300*4250mm |

| FEATURES OF PILLOW PRODUCTION LINE | ||

| ● PLC Control System The production line is controlled by PLC programming system , which is automatically feeding (polyester, microfiber,kapok), opening, weighing and filling . The weight can be set on the control box, and it's simple operated and with high efficiency. | |

| ● Accurate Weighing We use the quality weight sensor and the machine's weighing error/tolerance is less than 15 grams per filling. The material weighing speed is faster and it's accurate to ensure output of materials and the quality of fibers. | |

| ● High Efficiency This J-001-D2 highest filling capacities ranging from 1,000 pillows to 4,000 pillows per shift, from bale opening, carding, weighing and filling process, it can all controlled on the control box with only onesingle operator. | |

| ● Vacuum Filling Polyester fiber comes inevery corner of the pillow, by using our pillow production line, the pillow is more even, full and flat. This machine is suitable for pillowcases of various fabrics, fabric, nonwoven fabric, etc. There is no fiber flying in the filling process, clean and environmental protection. | |

| ● Automatic Feeding The bale opener can store 250-300kg fiber per hour, the fiber will be infeeded evenly to the fiber opener without manual feeding, saving labor cost. | |

| PROJECT CASES | ||

|  |  |

| 2013 in Dubai | 2014 in USA | 2015 in India |

|  |  |

| 2017 in Russia | 2018 in Korea | 2019 in Spain |

|  |  |

| 2020 in Malaysia | 2021 in India | 2023 in Indonesia |

| EXAMPLES OF FINAL PRODUCTS | ||

| ||