Views: 0 Author: Site Editor Publish Time: 2024-09-12 Origin: Site

Choosing the right pillow stuffing machine is a critical decision for manufacturers in the bedding and furniture industries. The type of machine you invest in can significantly impact your production efficiency, product quality, and bottom line. This guidance is aimed at business owners and production managers who are either starting a new pillow manufacturing venture or looking to upgrade their current equipment. In this article, we will explore the key considerations and steps to take when selecting a pillow stuffing machine to ensure it aligns with your business needs and objectives.

A pillow stuffing machine is an industrial device used to fill pillows, cushions, or similar products with stuffing materials such as cotton, polyester fiberfill, foam, or other synthetic fibers.

Fiberfill is a common pillow stuffing material made from synthetic fibers, often used in both decorative and support pillows for its lightweight and fluffy characteristics.

This term refers to the number of units a machine can produce within a specific timeframe, typically measured in units per hour.

Before diving into the options available, start by determining the scale of your production. Consider the following:

The volume of pillows you plan to produce daily or weekly

Types and sizes of pillows (e.g., standard, King, travel size)

Diversity in stuffing materials (e.g., synthetic fibers, foam)

There are several types of pillow stuffing machines available, each suited for different needs. Common types include:

Manual Stuffing Machines: Best for small-scale production or businesses just starting out.

Semi-Automatic Machines: Ideal for medium-scale production, offering a balance between manual input and automated processes.

Fully Automatic Machines: Suitable for large-scale production, providing high efficiency and consistency with minimal manual intervention.

Look for essential features that align with your production requirements, such as:

Adjustable stuffing speeds

Different stuffing methods (e.g., blown fiberfill, foam cutting and injection)

Compatibility with various stuffing materials

User-friendly interface and ease of operation

Maintenance requirements and ease of cleaning

Research potential manufacturers or suppliers. Look for reviews, testimonials, and any certifications that attest to the quality and reliability of their machines. Engage with industry forums or associations to gather feedback from other businesses using similar machines.

While the initial purchase price is critical, don’t overlook the long-term costs such as:

Maintenance and repair costs

Energy consumption

Availability and cost of spare parts

Training expenses for operators

If possible, request a demonstration or trial period to see the machine in action. This hands-on experience can provide invaluable insights into its operation, efficiency, and suitability for your production line.

Use a checklist or comparison table to weigh the pros and cons of each machine you are considering. Key parameters to include are:

Production capacity

Flexibility with materials

Ease of use

Costs (initial and ongoing)

Manufacturer support and warranty

After thorough comparisons and evaluations, choose the machine that best meets your criteria. Ensure that you have all necessary support and training materials from the manufacturer to ensure seamless integration into your production process.

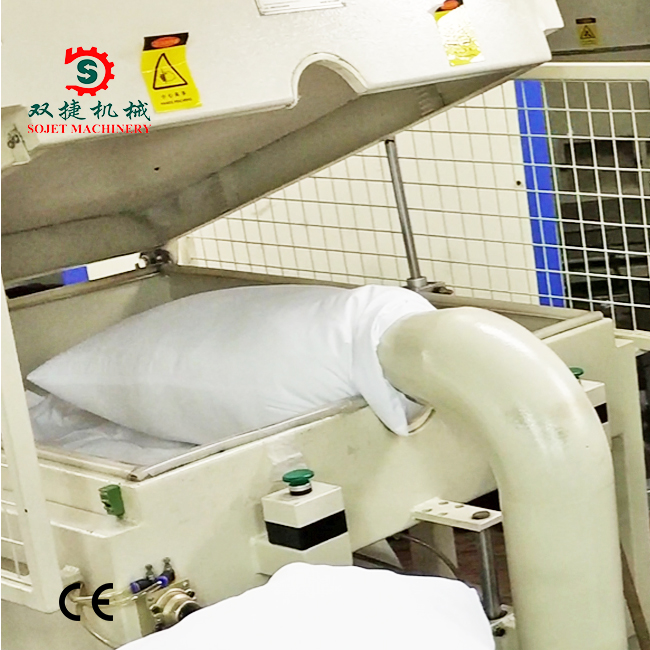

Elevate your pillow production with the Sojet High-Capacity Automatic Pillow Filling Machine, engineered to handle all types of fibers with exceptional efficiency and precision. This state-of-the-art machine features adjustable stuffing speeds, ensuring optimum filling consistency for every pillow.

Its advanced fiber feed system guarantees uniform distribution of materials like polyester, foam, and mixed fibers. With an intuitive control panel, operation and maintenance are straightforward, minimizing downtime and maximizing productivity. This machine not only boosts your production capacity but also enhances the overall quality of your pillows. Invest in the Sojet High-Capacity Automatic Pillow Filling Machine today to take your manufacturing to the next level and stay ahead in a competitive market.

Choosing the right pillow stuffing machine is just the beginning. Here are some essential tips and reminders to help you get the most out of your investment with Sojet:

Custom Design: Our sales and R&D team at Sojet can assist you in developing the best possible pillow production lines tailored to meet your specific requirements. By collaborating closely with you, we ensure that the machine is customized to maximize efficiency and product quality.

Machine Installation and Training: Our team of experts provides on-site installation and comprehensive training programs. This ensures that your operators can use the machinery effectively and safely, reducing the learning curve and enhancing productivity.

Technical Support & Maintenance: At Sojet, customers are our priority. We offer regular maintenance services to keep your machines in optimal condition, thereby reducing downtime and prolonging their lifespan. Our prompt repair services are designed to minimize disruptions and keep your production running smoothly.

Upgrades and Modernization: As technology evolves, Sojet provides upgrades and modernization services to keep your machinery at the forefront of the industry. Staying updated with the latest advancements ensures your production line remains efficient and competitive.

Spare Parts Supply: We maintain a comprehensive inventory of essential spare parts. This enables your production lines to minimize downtime caused by malfunctions, ensuring a seamless manufacturing process.

Consultancy Services: Our team offers consultancy services to help you optimize your production processes. By analyzing your current setup, we can recommend improvements to boost overall efficiency and productivity.

Choosing the right pillow stuffing machine involves careful consideration of your production requirements, machine features, and long-term costs. By assessing your needs, researching thoroughly, and comparing options, you can make an informed decision that aligns with your business goals and enhances your production efficiency. Remember, the right machine is an investment in your business's future success.