Views: 0 Author: Site Editor Publish Time: 2025-11-13 Origin: Site

In today’s highly competitive food industry, packaging plays a pivotal role in ensuring product freshness, extending shelf life, and attracting consumers. Among the many packaging technologies available, pillow vacuum packing machines have emerged as a popular solution for both small and large-scale food producers. These machines combine efficiency, reliability, and flexibility to meet the demands of modern food processing. In this article, we explore the latest innovations in pillow vacuum packing machines, their applications in the food industry, and the benefits they offer to manufacturers and consumers alike.

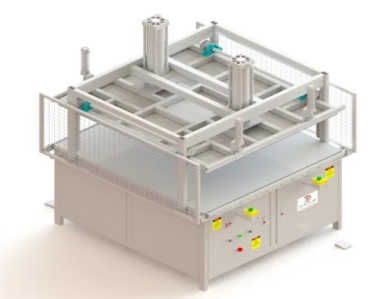

A pillow vacuum packing machine is a type of packaging equipment designed to seal products in a pillow-shaped bag after removing air from the package. Unlike other vacuum packing methods, this type of machine produces soft, pillow-like packs that are easy to handle, stack, and transport. The vacuum environment not only reduces oxygen exposure but also helps maintain food quality by slowing down oxidation, microbial growth, and moisture loss.

Pillow vacuum packaging is especially popular for snacks, bakery items, coffee, dried fruits, nuts, and other products that benefit from airtight packaging. These machines can be used in both manual, semi-automatic, and fully automatic operations, making them adaptable to various production scales.

In recent years, pillow vacuum packing machines have undergone significant technological advancements, driven by the food industry’s demand for higher efficiency, improved product safety, and better cost-effectiveness. These innovations allow manufacturers to maintain product quality while optimizing operations.

Modern pillow vacuum machines are increasingly equipped with PLC (Programmable Logic Controller) systems and intuitive touch-screen interfaces. These advanced control systems simplify operation, reduce errors, and ensure consistency across batches. Operators can precisely adjust vacuum levels, sealing temperatures, and packaging speed, tailoring the process to each product’s specific requirements.

For example, delicate items like potato chips, pastries, or soft cookies are highly susceptible to crushing if exposed to excessive vacuum pressure. Adaptive vacuum control systems automatically regulate vacuum strength based on the fragility of the product, protecting it from damage while still maintaining optimal packaging. Similarly, the ability to pre-program multiple product profiles allows manufacturers to switch between product lines efficiently, reducing downtime and increasing overall throughput.

One of the most notable innovations in pillow vacuum packaging is the integration of multi-functional capabilities into a single machine. Beyond vacuum sealing, modern machines can also:

Date-stamp or batch-code products for traceability.

Gas-flush packages with nitrogen or CO₂ to extend shelf life for sensitive products such as coffee, tea, dried fruits, and nuts.

Seal multiple layers of films for added protection or branding purposes.

Gas-flushing, for instance, creates an inert atmosphere inside the package that minimizes oxidation and preserves flavor, aroma, and color. This feature is particularly important in premium snack foods and beverages where freshness is critical for customer satisfaction.

Energy efficiency has become a central focus for modern pillow vacuum machines. Many units now incorporate low-power vacuum pumps, optimized heating elements, and energy-saving operational modes. These features reduce electricity consumption without compromising performance.

Additionally, manufacturers are responding to environmental concerns by offering machines that are compatible with recyclable and biodegradable packaging films. Some models are designed with eco-friendly construction materials or incorporate energy-recovery technologies, which capture heat from sealing elements and reuse it to reduce overall energy costs. This combination of efficiency and sustainability supports both operational savings and environmental responsibility.

Sealing is a critical component of vacuum packaging. Advanced pillow vacuum machines feature dual heating bars, precision sealing jaws, and uniform pressure distribution to create airtight seals, even on uneven or irregular products. High-strength seals prevent leaks, reduce spoilage, and increase product durability during shipping and storage.

Some machines are compatible with multi-layered, laminated, or biodegradable films, allowing manufacturers to produce premium packaging while meeting eco-conscious standards. The improved sealing technology also helps in reducing material waste, as fewer packages are rejected due to improper sealing.

Automation has revolutionized pillow vacuum packaging, allowing high-speed production without sacrificing quality. Modern machines integrate conveyors, automated product feeders, and film rollers, creating a continuous workflow.

High-speed pillow vacuum machines are ideal for large-scale food processing plants, enabling production rates of hundreds to thousands of packs per hour. Many machines can also be linked to factory monitoring systems, providing real-time data on output, machine health, and maintenance schedules. This integration reduces unplanned downtime and ensures efficient management of resources.

Pillow vacuum packing machines are versatile and capable of handling a wide range of food products, from snacks to frozen meals. Their ability to preserve freshness, extend shelf life, and improve logistics makes them an essential tool in modern food processing.

Snack foods like chips, popcorn, pretzels, and puffed snacks are highly sensitive to oxygen exposure, which can cause staleness and loss of crunchiness. Pillow vacuum packaging removes air from the package, protecting the product from oxidation while maintaining its shape and texture. Multi-layered films can also add barrier properties that prevent moisture absorption, further extending shelf life.

Baked goods, pastries, cookies, and chocolates are delicate and prone to moisture loss or deformation. Vacuum packaging protects these products from environmental factors such as humidity and contamination. Additionally, multi-layer films with printed designs allow manufacturers to combine product protection with brand promotion, creating visually appealing packaging that stands out on shelves.

Coffee beans and loose-leaf teas are extremely sensitive to oxygen, which can quickly degrade flavor and aroma. Pillow vacuum machines with nitrogen gas-flushing capabilities create an inert environment that preserves freshness for extended periods. Some advanced machines also allow customized packaging profiles for different roast levels, ensuring optimal shelf life for premium products.

Products like almonds, cashews, raisins, and dried mangoes benefit greatly from vacuum packaging, which prevents moisture ingress and microbial contamination. Pillow vacuum packs maintain the natural taste, texture, and crunchiness of nuts and dried fruits while enabling efficient stacking and storage for logistics and retail purposes.

Frozen meals, pre-cooked dishes, and ready-to-eat foods require airtight packaging to prevent freezer burn and maintain portion integrity. Pillow vacuum packs are compact, lightweight, and stackable, maximizing storage efficiency in freezers and reducing shipping costs. The machines’ high-speed automation ensures rapid packaging without compromising the product’s structural integrity or taste.

Pillow vacuum packing machines offer multiple advantages for food producers:

By removing air and creating an airtight seal, these machines prevent oxidation, microbial growth, and moisture loss, significantly extending the product’s shelf life.

Vacuum packaging preserves texture, aroma, and taste. High-quality sealing ensures no leaks or contamination, maintaining consumer confidence.

Although initial investment may be high, pillow vacuum machines reduce packaging material waste and improve storage efficiency, ultimately lowering long-term operational costs.

These machines accommodate various product sizes and film types, providing flexibility for different product lines and promotional packaging.

Modern machines adhere to international food safety standards (like ISO and HACCP), ensuring that packaged products meet regulatory requirements for hygiene and safety.

When selecting a pillow vacuum packing machine, food producers should consider:

Production capacity: Ensure the machine can handle the desired output volume.

Product type: Fragile or perishable products may require adjustable vacuum and sealing settings.

Automation level: Fully automatic machines are ideal for large-scale operations, while semi-automatic units suit smaller production lines.

Film compatibility: Consider eco-friendly or multi-layer films based on sustainability goals.

Maintenance and support: Reliable after-sales service and easy maintenance are critical for minimizing downtime.

The pillow vacuum packing industry is continuously evolving. Key trends include:

Integration with smart factory systems for real-time monitoring and predictive maintenance.

Eco-friendly packaging solutions, including biodegradable films and recyclable components.

Hybrid machines capable of combining vacuum packaging with modified atmosphere packaging (MAP) for perishable foods.

Improved user interfaces and automation to reduce labor dependency and increase operational efficiency.

Pillow vacuum packing machines have transformed the way the food industry approaches packaging, offering a combination of durability, efficiency, and product preservation. By leveraging intelligent control systems, multi-functional capabilities, and high-speed automation, food manufacturers can ensure their products reach consumers in optimal condition.

For businesses looking to enhance their packaging operations with the latest innovations in pillow vacuum packing, www.sojetmachine.com provides a range of high-quality, reliable solutions. Their machines are designed to meet diverse food industry needs while improving efficiency, reducing waste, and maintaining product integrity. For more information or to explore the right packaging solutions for your business, visiting www.sojetmachine.com or contacting their team is highly recommended.